When it comes to protecting metal components from corrosion, advanced corrosion prevention packaging is no longer optional—it’s essential. Industries like automotive, aerospace, electronics, manufacturing, and defense depend on high-performing materials to protect metal assets during storage and shipping. Enter the Cortec® VpCI®-126 Series film, one of the most innovative solutions for vapor phase corrosion protection on the market today.

Texas Technologies specializes in high-quality industrial packaging solutions, including the full line of Cortec® VpCI® products, designed to shield metals from rust, oxidation, and environmental damage. Let’s dive into why the VpCI®-126 film is a must-have for any business looking to protect its metal goods with confidence.

What is Corrosion (And Why Does It Matter)?

Corrosion is a natural chemical reaction that occurs when metals interact with moisture, oxygen, or harsh chemicals. Over time, this leads to rust, pitting, staining, and metal degradation – all of which can compromise structural integrity and lead to expensive repairs or replacements.

In industries with complex supply chains and long-term storage needs, corrosion control is critical to maintaining performance, safety, and product lifespan. That’s where VpCI® packaging solutions come in.

What Is Cortec® VpCI®-126 Film?

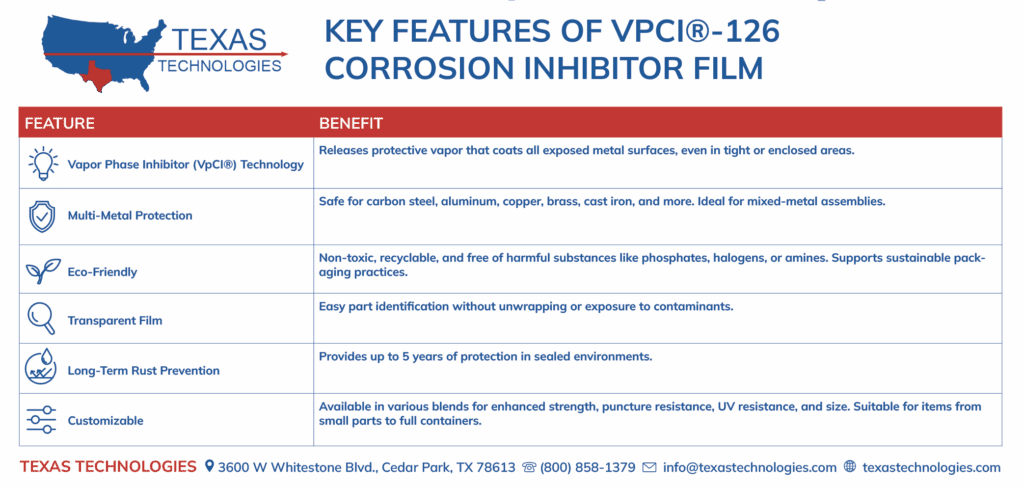

VpCI® (Vapor phase Corrosion Inhibitor) 126 Series film is a high-performance corrosion protection film engineered to safeguard metal surfaces from degradation during manufacturing, shipping, and storage.

Unlike traditional rust preventatives like oils or greases, which require messy cleanup, VpCI®-126 film offers clean, dry, and invisible protection. It works by releasing corrosion-inhibiting vapors that form a molecular protective layer on all metal surfaces—even in hard-to-reach areas.

Applications Across Industries

The VpCI®-126 film is ideal for a variety of industrial applications:

- Export packaging of sensitive equipment

- Long-term storage of tools and machine parts

- Interplant shipping of raw materials and assemblies

- Military packaging requiring MIL-SPEC standards

- OEM packaging in electronics, automotive, and more

Why VpCI®-126 is Better Than Traditional Rust Prevention

Conventional rust prevention methods, such as applying oils, sprays, or desiccants, can be time-consuming and messy. They often require cleaning or degreasing before the parts can be used—adding time, labor, and cost.

With Cortec® VpCI®-126 film, parts can go directly from the packaging to production or installation. No degreasing. No wiping. No cleanup. Just efficient, reliable protection.

Environmentally Responsible, Industry-Compliant

VpCI®-126 film complies with numerous global and industry standards for safety and sustainability. It’s an excellent choice for companies looking to reduce chemical use, eliminate hazardous waste, and align with ESG goals.

Ready to Upgrade Your Corrosion Prevention Strategy?

Texas Technologies is proud to be a trusted distributor of Cortec® corrosion control solutions. Whether you’re packaging precision metal components or shipping heavy-duty machinery, our team can help you find the right VpCI® film, bags, and corrosion-inhibiting materials to meet your needs. Browse our Cleanroom & Corrosion Control Products to explore additional solutions, or go straight to the VpCI®-126 Series Films to find the exact fit for your application. Need help choosing the right product? Contact our packaging experts today for guidance, custom orders, or a free quote.

Flip through this digital document to dive deeper into packaging solutions for corrosion control and prevention:

To learn more about the science behind VpCI® corrosion prevention, watch this short video!